The University of Miami College of Engineering has established a chemical and materials characterization facility designed to support advanced research in infrastructure materials, environmental sustainability, and biomedical applications. The facility features cutting-edge instruments for analyzing and testing a wide range of materials, enabling innovation across multiple engineering and scientific disciplines.

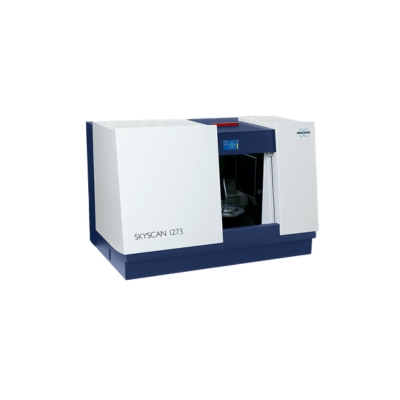

Key equipment includes tools for surface area measurement, X-ray diffraction for elemental and crystal phase analysis, thermogravimetric analyzers, differential calorimeters, and X-ray CT tomography systems. These resources are critical for research into material properties, durability, and performance under various conditions.

The facility also includes workspaces with chemical and biological hoods and is actively used by more than 10 faculty members, including four from the Civil and Architectural Engineering Department, along with over 40 undergraduate and doctoral student researchers. Researchers from other universities also use the facility. Support for instrumentation is provided by companies such as Shimadzu Corporation.

Located on the fifth floor of the McArthur Engineering Building in a newly remodeled, state-of-the-art space, the facility serves as a hub for innovation and collaboration in materials research.